About us

We are a fast-growing, mid-sized company based in South Thuringia in Germany, a region with a centuries-old tradition of tool manufacturing.

This is where we work with our team of around 400 employees to develop, manufacture and market our pro-quality tools.

On 1 July 1991, we became an independent subsidiary of the prestigious KNIPEX-Werk C. Gustav Putsch KG in Wuppertal (NRW, Germany). Since then, we have transformed ourselves into a successful and integral part of the KNIPEX Group.

Our company’s traditional roots lie in our factory in the Altersbach district of Steinbach-Hallenberg, where production was already underway in 1959 with a workforce of 29. Today, we are one of the world’s most productive makers of quality tools for construction and industrial use.

In the early 1990s, we expanded our product portfolio to include pro-quality tools for the cutting, stripping and crimping of cables. At the time, we were looking to move into other segments, and a former RENNSTEIG director suggested tools for cables, because cables and power would be just as much in demand 100 years from now. Ever since, we’ve been making high-quality tools for cable assembly at our company head office in the Viernau district of Steinbach-Hallenberg.

Thanks to our efforts, we are now one of the leading suppliers to this industry worldwide.

Quality tools

for construction and industry

We produce quality tools for use in construction and industry at our facility in the Altersbach district of Steinbach-Hallenberg. From here, we ship out many thousands of chisels, pin punches, pry bars, screw extractors, hollow punches and pipe spanners each and every month.

We manufacture our products with modern, industrial methods using materials of the very highest quality. As our customer, this ensures you enjoy optimum quality and longevity when using our RENNSTEIG products.

Quality tools

for cable assembly

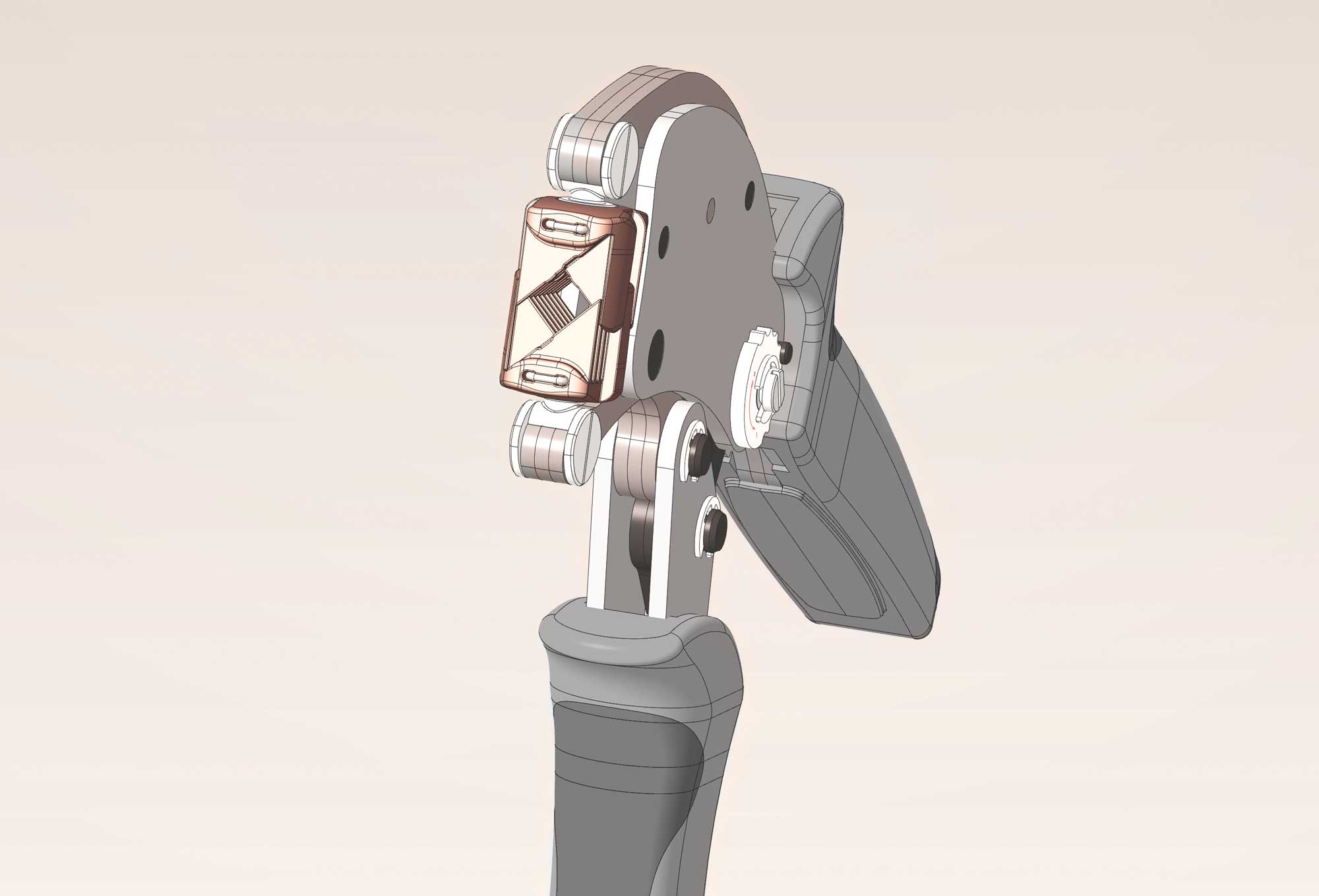

We produce handheld tools and crimping machines for cable assembly at our company head office in the Viernau district of Steinbach-Hallenberg. These tools find use in the skilled trades, manufacturing, service, maintenance, prototyping and low-volume production. Our international segments range from electrical installations in construction through to wiring harness production in aviation. All of our tools are designed to promote longevity and ergonomics, to ensure the optimum handling of your day-to-day jobs as a professional.

High-quality tools made in Germany

When making our tools, we utilise tried-and-tested production techniques that we continuously optimise and enhance with a range of innovative technologies.

Almost all of our production activities are completed in-house. Where necessary, we work with our long-standing business partners, who are also based in our region. This ensures we keep tight control of our production workflows, and can directly influence and safeguard our product quality. From conceptual design to shipping out the finished tool, almost everything is completed under one roof.

Our QA work is carried out by a team of highly qualified and dedicated employees, who are supported by the Quality Dept. to conduct in-process as well as more extensive quality controls. Our in-house Test Lab provides a wide range of ultramodern testing and measuring equipment to complete this work.

Our quality management system is deeply integrated to cover functionality across the full spectrum of business processes.

From the initial idea to a standard product

Apart from expanding our production capacities and continuous improvements to our production processes, we are also keen to keep expanding our product portfolio. As a result, our in-house R&D Dept. produces a steady stream of new products while also making optimisations to existing tools. A large library of patents – not restricted solely to German territory – also document our innovative strengths.

Our exceptional flexibility in production has also enabled us to specialise in the creation of unique, customer-specific tools for use in a very wide range of industry applications. Brought into their development processes at an early stage, we work closely with them to develop effective solutions. For many years, leading German and global companies have been relying on our know-how, our flexibility and our industry expertise.

The secret to our success from the start:

our employees

From the earliest days of our company, our business has been founded on the technical expertise, creativity and dedication of its employees. Our workforce has also more than doubled over the last 30 years.

Which is why we believe it is so important for us to create a welcoming working environment. In doing so, we not only ensure good working conditions and equipment but also invest in options for further training, health programmes and improving the job/life balance.

One of the most important investments in our future is the training provided by our in-house academy, the RENNSTEIG ‘Forge of Heroes’. Two full-time trainers work here on securing the skills that are needed by our future specialists.

In fact, we have always emphasised the importance of training and employee retention: the first apprentice we took on after completing his training in 1991 still works at the company. We now typically train around six apprentices each and every year.